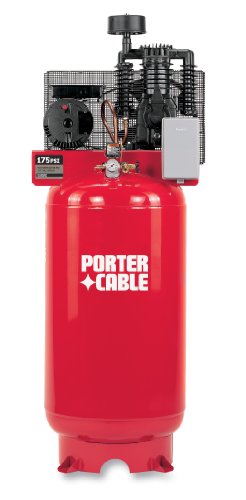

Buy Porter-Cable CPLMC7580V2C 30 Amp 7.5 Horsepower 80 Gallon Oiled Vertical Compressor

Buy Porter-Cable CPLMC7580V2C 30 Amp 7.5 Horsepower 80 Gallon Oiled Vertical CompressorPorter-Cable CPLMC7580V2C 30 Amp 7.5 Horsepower 80 Gallon Oiled Vertical Compressor Product Description:

- 175 psi - 195 gal equivalent tank size as compared to conventional 125 psi model

- 80 gal air tank supports heavy duty, continuous multi-tool usage

- 240-volt capacitor start induction motor with manual thermal overload protection

- Two stage, oil lubricated pump designed with stainless steel valves, cast iron cylinder body and sleeves for long and dependable service life

- Aluminum crankcase and head for cooler operating temperatures Pump contains automotive style pistons, rings, and connecting rod

Customer Reviews

Most helpful customer reviews

10 of 10 people found the following review helpful.![]() lot of work means a lot of air

lot of work means a lot of air

By A Customer

This compressor seems to be a good choice. I work with stained glass and this compressor meets the needs for working with glass. Glass needs a lot of air and - continuous air. This compressor meets all of my other work needs also...... power tools, air guns and just about any other tool you can think of. We started out with a 60 gallon, but decided to go to 80 gallon. That was the icing on the cake. No problems, excypt it's not very mobil. It's great where it's at.

7 of 7 people found the following review helpful.![]() Great Compressor

Great Compressor

By Big-D

I took delivery of my new Porter-Cable compressor only 7 days after ordering it. And free shipping too! Amazon did a great job getting it to me quick.This compressor suits my needs to a Tee. Although I use it in my garage, it is a commercial rated compressor. I rate it 5-Stars. It looks great also. The massive motor and compressor actually runs much quieter than the 3.5hp oil-less I replaced. I decided on this model because I wanted the air volume to run any tool I have, without the fear of it being under powered. I can run my DA Sander continuously and when the compressor kicks on at 145psi, it fills back up in just a minute, even while I continue with my DA.This Porter-Cable compressor in my garage was long over due. After owning it now for several months, I can honestly say, it suits all of my compressor needs. It operates great and supplies plenty of air power to run any of my air tools.

7 of 7 people found the following review helpful.![]() This is perhaps one of the best compressors on the market.

This is perhaps one of the best compressors on the market.

By Max Anthony

This is an excellent compressor. I was a little iffy as most are buying a name brand like Porter Cable which isn't known with a history of air compressors but i'm glad to see all my doubts dissapear. I had an ingersol rand vertical upright compressor before so this is not my first rodeo. This Porter Cable easily smokes the Ingersol Rand both in power and in price.PURCHASE:Anyone who's done a little foot work on the internet and in local stores will see that this compressor delivers more bang for the buck then virtually any other compressor on the market right now. The 175PSI @ 25SCFM really is as powerful as they say it is. Do not use the compressor without a regulator, that would be highly dangerous, for any compressor but especially this one. I also bought from amazon because I read a review here and it said free shipping and free lift gate service. Well that was not the case. The only thing Amazon shipped me free was my bucks even on nearly a $2000.00 order. *grumble grumble* Maybe it has something to do with location? (Although I do live in lower contiguous 48 states. After my purchase it was shipped from grizzly so really I don't know what the difference between buying it here or at grizzly would be since you have to pay freight and lift gate both ways. And yes you do need the lift gate. This thing comes in a mammoth size box on a fairly good size pallette and it is top heavy. Not something you'd want to ramp unless you had a team of friends helping you. When it got here I found it to be packaged quite well although they only used stiff cardboard around the unit not wood. This may be why some complain about shipping damage. I had virtually no shipping damage. Part of the wire mesh fan housing was slightly bent, but easily bent back into shape. Overall a great purchase. You can't beat this compressors quality and capability in this price range. An ingersol rand or chicago pneumatic will cost you twice as much for the same specs and still be the same quality as this machine.SETUP:The first thing everyone asks is do they have to bolt it down and can they plug it into a dryer outlet. The answer is yes to both with some caveats. First you may void your warranty if you ever tell someone or show someone it's not bolted down or that you haven't hard wired it. But first lets just talk about mounting it. If this is a permanent installation by all means bolt it to the concrete but in doing so get yourself some good bolt-through shock/vibration machine mounts. You can get these through companies like MSC Industrial, JL Industrial, Grizzly Tool, Lord Vibration Isolators and Farrat.com but machine mounts are not cheap (15$-25$ usually a piece) but if your bolting it down get the right thing and have a sales person help you.With that said, the machine has very little vibration and most people, myself included, will testify that this machine is not as loud as most people will think it is. It also stores so much air that unless your sandblasting your prolly not going to have it continuously running. Thus I decided to build a non-bolted down base for the compressor. I did this with my ingersol vertical compressor and never had a problem with it either. I took 4 boards, 2 of which were 2x6's the others to be under them were 2x8's and used PL and screws to join them lincoln log style. I did it in such a way that I can reach my arm easily into the bottom of the tank to unscrew that drip valve when needed. Once I had these boards setup I shimmied the compressor on there to mark the drill holes. Why they used such giant bolt holes on the compressor is beyond me. I ended up using a metric fastener to give perfect nearly zero clearance in those holes. Of course this means big bolts. Once the holes were drilled I painted the thing black and then I attached 4"x4" by 3/4" thick vibration pads to the bottom with exterior mounting tape (it has a red backing). The ones I prefer are cheap at 10$ a piece from KELLETT Enterprises, Inc http://www.kellettent.com/vibration.html From here I actually put some thin rubber under the feet of the compressor and bolted the compressor down. Use washers top and bottom. I also used a rubber washer under my top washer so that the compressor foot wasn't metal to metal with my bolt. Little things like this do help with dampening. With the whole thing on a nice base with the antivibration pads from Kellett I would bet that my compressor is dampened more then any compressor bolted to the concrete in virtually any shop. Here are some pics(you'll have to copy / paste them into your browser as amazon doesn't let you do html)http://home.comcast.net/~theonyxabyss/aa/compressor/compressorsmall.jpg(Above: Yah I took off the cheezy stickers hehe You might want to zip tie the wire that goes right next to the globe valve to the other black wire/motor wire to keep it away from the globe valve like I did)http://home.comcast.net/~theonyxabyss/aa/compressor/5443.jpg(Above: you can see the foot resting on a thin piece of rubber and it's bolted down with correct size hex bolt which also has washer and rubber washer. Don't forget to use a washer underneath or your bolt will just pull into the wood when tightening, especially if its soft lumber)http://home.comcast.net/~theonyxabyss/aa/compressor/5444.jpg(Above: Here you can see the stand I made with Kellett pads underneath it. These pads are great. Some prefer the cork 4x4x1" from places like MSC but i've never tried them and these pads are for supporting heavy duty compressors as well as thousand pound industrial washing machines so you can be sure they are the right thing for the job. A washing machine has way more vibration then a compressor.)WIRING:Now that you have your compressor either bolted down or mounted onto an antivibration setup you'll probably want to wire up the electrical. It is a three wire setup to the gray electrical box on the front. So the 220Volt 30Amp is comprised of 2 hots and one ground. If you are hardwiring this unit in you will want to buy dual-pull 30 amp breakers (I suggest slim-line as they only take up one slot). If your unsure about electrical get an electrician to help you hard wire in it. If you do not wish to hardwire it in you can actually run this compressor off a dryer cord that is for 220V 30Amps and has three wires. About the tricky party is stuffing the three wires through the electrical connector on the side of the box. I used some silocne spray to get the dryer cord through there as it was a little stiff. The two red wires at the top of the fused area are is the hot area and this is where you'll connect your two hot wires to. The ground you'll connect to where the two green wires are already bolted down to.Once you have that wired in safe and securley you'll be able to run the compressor. If you have one of those newer dryer plugs with the four poles you'll have to ask about wiring up a three wire compressor to it. Google it as i've heard that come up a lot. Also if someone tells you that a plug increases resistence they are wrong, that kind of resistence is very minimal when compared to the resistence you get from running long distances with 220 line. Your dryer is "plugged" into the wall the same way and so is my welder. No heat even remotely noticable in the 220 line, the outlet, nor the dryer cord when I ran the compressor for 25 mins straight so I can tell you this is a safe way to wire the unit and it is fully grounded. One caveat, if you use a cord make sure to use the shortest cord possible on the compressor 6' is best.. 8' i'd say should be your maximum. With electrical hardwired runs you always want to go for the shortest run possible to decrease resistence. If your close to the breaker box (under 50') it's not even worth mentioning, you'll be fine.RUNNING IT:It runs quieter then most expect but its still a vertical compressor. The tank fills fast and make sure you do the 20 minute run in test in the manual. Also make sure you get a torque wrench or borrow one and calibrate those head bolts as the manual says after 5 hours of running. During the break in procedure I realized there was some excess vibration with a clinking noise cominig from the electrical box cover. The way the cover mounts to the electrical box is poorly engineered and it rattles making a metallic clinking sound. I ended up gluing a rubber shim with PL Premium polyurethane adhesive to the top of the elctrical box so that when the cover goes on it sits on the rubber in between the two portions of raised metal which seat the cover. Then when it ran it ran quietly without any vibraton from that box cover.Overall:In all i'm very pleased with the buy. The instructions are decent and have pictures in them but they are very short and don't really give you as much information as I would have liked to see. Here is a good diagram for those with concerns on how to setup the lines to the compressor.http://www.oldsmobility.com/images/ACpipinglayout1.jpgIf you have questions about setup hop onto a air compressor forum and describe your shop and your work and they'll give you plenty of good ideas on how to get the most bang out of this machine. Between building the anti-vibration stand, wiring it up and all the other little things I had to do to get this beast lifted into the shop it was some work but work well worth it. I would give this compressor a 5/5 stars and I would definitely reccomend it as serious choice for any shop who wants a high quality robust compressor. If you would like to see my compressor running "full open" during the 20min manufacturers reccomended break in cycle you can copy this link into your browswer and see my machine runninghttp://home.comcast.net/~theonyxabyss/aa/compressor/5441.aviIt's 7megs so it might take a moment to load. You can see it runs smooth. Most of what your hearing is my camera right in front of the globe valve which is turned "full open" letting copious amounts of air out at a deafening level. You'll never run the compressor this way after the break-in.Now get that compressor fired up and lets start building! :P

Latest Price: See on Amazon.com!

More Info: See on Amazon.com!

See Customers Review: See on Amazon.com!